Heat Treatment: What It Is and Why It’s Necessary

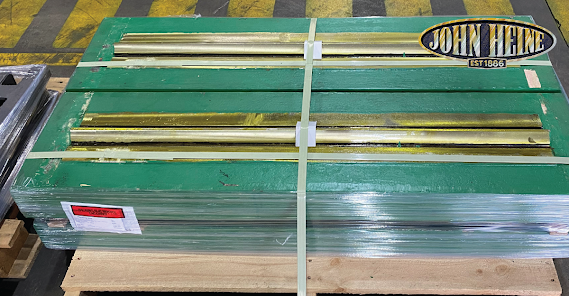

As manufacturing processes become more complex and demanding, metal pieces must be able to withstand wear and tear. That’s where heat treatment comes in. Heat treatment is necessary for several reasons, including allowing a metal or alloy to be improved to withstand wear and tear better. In this article, we’ll explore the basics of heat treatment Australia and discuss its importance in manufacturing. We’ll also introduce you to Johnheine — the best machining shop in Sydney, Australia, and explain why they’re such a valuable resource regarding heat treatment. So, whether you’re looking to learn more about metal pieces or need some advice on where to find the best heat treatment services, read on! What is heat treatment? Heat treatment is a process by which metal is heated to a specific temperature and then cooled to harden the material. This allows metal pieces to withstand wear and tear, making them more durable in manufacturing. Why is heat treatment necessary? The main reasons t...